-

Optical Quartz Glass

-

Machining Quartz Glass

-

Quartz Glass Tube

-

Quartz Capillary Tube

-

Borosilicate Glass Tube

-

Quartz Glass Rod

-

Laser Spare Parts

-

Silicon Dioxide Sputtering Target

-

Quartz Apparatus

-

Quartz Glass Plate

-

Custom Glass Parts

-

Custom Ceramic Parts

-

Optical Manufacturing Equipment

-

Mobile Glass Cover Making Machine

-

Optical Measuring Instrument

-

Optical Crystal

Magnesium Fluoride Mgf2 Crystal Structure Tetragonal

| Crystal Structure | Tetragonal | Lattice Constant | A=4.62 Å,c=3.06 Å, |

|---|---|---|---|

| Melting Point(℃) | 1255 | Crystal Growth Method | Bridgeman, Crucible Descent Method |

| Density(g/cm3) | 3.18 | Hardness | 4(mohs) |

| Thermal Expansion Coefficient(/℃) | 13.7×10-6 (∥c),8.9×10-6 (⊥c) | Thermal Conductivity /Wm-1K-1 | 0.3@300K |

| Refractivity | No=1.37608 Ne=1.38771(0.7μm) | Transmission Wavelength | 0.2-6.00μm |

| Highlight | magnesium fluoride mgf2 crystal,structure tetragonal mgf2 crystal |

||

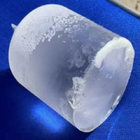

Magnesium Fluoride Crystal (MgF2)

Magnesium fluoride crystal (MgF2) belongs to the tetragonal crystal system, with a melting point of 1255 ℃, high hardness, good mechanical properties, stable chemical properties, and less prone to deliquescence and corrosion. The main characteristic of its optical performance is its high transmittance in the vacuum ultraviolet band. It is widely used in fiber optic communication, military industry, and various optical components.

Application:

Widely used in fiber optic communication, military industry, and various optical components.

Features/advantages:

High hardness;

Good mechanical and chemical properties;

Not easily deliquescent and corroded;

High transmittance in the vacuum ultraviolet band.

Parameters:

| Crystal structure | Tetragonal |

| Lattice constant | a=4.62 Å,c=3.06 Å, |

| Melting point(℃) | 1255 |

| Crystal growth method | Bridgeman, Crucible descent method |

| Density(g/cm3) | 3.18 |

| Hardness | 4(mohs) |

| Thermal expansion coefficient(/℃) | 13.7×10-6 (∥c),8.9×10-6 (⊥c) |

| Thermal conductivity /Wm-1K-1 | 0.3@300K |

| Refractivity | no=1.37608 ne=1.38771(0.7μm) |

| Transmission wavelength | 0.2-6.00μm |

| Transmittance | > 90% @ 0.2-6.00μm |

| Dimension | 5x5,10x10, 20x20,Ø50.8mm. |

| Thickness | 0.5mm,1.0mm or customized |

| Polishing | Single or double sided |

| Crystal orientation | <001>±0.5º |

| Precision of crystal orientation | ±0.5° |

| Edge orientation accuracy: | 2°(Special requirements up to 1°) |

| Oblique cut wafer | Wafers with edge oriented crystal planes that can be processed according to specific needs and tilted at a specific angle (tilt angle 1 ° -45 °) |

| Ra: | ≤10Å(5µm×5µm) |

| Packing: | Class 100 clean bag, Class 1000 ultra clean room |