-

Optical Quartz Glass

-

Machining Quartz Glass

-

Quartz Glass Tube

-

Quartz Capillary Tube

-

Borosilicate Glass Tube

-

Quartz Glass Rod

-

Laser Spare Parts

-

Silicon Dioxide Sputtering Target

-

Quartz Apparatus

-

Quartz Glass Plate

-

Custom Glass Parts

-

Custom Ceramic Parts

-

Optical Manufacturing Equipment

-

Mobile Glass Cover Making Machine

-

Optical Measuring Instrument

-

Optical Crystal

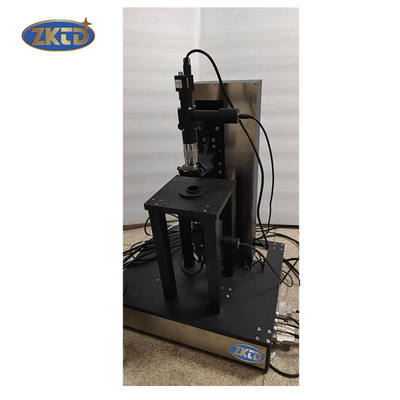

Zktd- Ncc100 Non Contact Optical Measuring Instrument For Curvature / Center Thickness

| Z-axis Stroke | ±20 Mm | XY Axis Stroke | 50 Mm |

|---|---|---|---|

| Z-axis Resolution | 0.1 Um | Z-axis Accuracy | 1 Um |

| XY Resolution | 1 Um | Measuring Ring Diameter | 20/35/45/70/90 |

| Accessory | Flat Crystal, Measuring Ring | Measurement Accuracy | 0.01% - 0.05 % |

| Measuring Time | Within 10 S (absolute) Within 2 S (comparison) | Thickness Range | [0.1, 35] Mm |

| Highlight | non contact optical measuring instrument,center thickness optical measuring instrument,curvature thickness optical measuring machine |

||

Optical Measuring Instrument ZKTD- NCC100 Non-Contact Curvature/Center Thickness Measuring Instrument

This non-contact measuring device for the curvature radius and center thickness of a single lens, can be applied to the transparent and non-transparent lenses of plane, convex, concave and other types of surface shapes. It has no restrictions on surface finish and materials. It has the characteristics of non-contact, high precision and wide applicability.

Instrument characteristics

(1) Non-contact measurement. The optical probe with long working distance is used to avoid scratches on the measurement introduction surface;

(2) Fully automatic measurement. With automatic centering, it can accurately calculate the curvature radius and center thickness, reducing installation requirements.

Precautions

(1) This equipment is a precision measuring equipment. The measuring accuracy is closely related to the relative position of the upper and lower probes. Please do not move, collide or disassemble it;

(2) It is recommended to place the equipment on the optical vibration isolation platform;

(3) When measuring the center thickness, the lens shall be kept in a nearly horizontal position and shall not tilt too much;

(4) It is suggested to use a standard gauge block to calibrate the probe distance before measuring the center thickness to improve the measurement accuracy;

(5) When the lens is visible to the red light, another surface may be observed during the measurement. If the lower probe observes the reflected spot on the upper surface, the spot shape is obviously different from the common shape at this time, so it needs to be distinguished.

![]()

As optical glass processing factory, we aslo specialized in optical manufacturing equipment for many years. We mainly supply Optical Glass and Crystal Processing Equipment, Mobile Phone Cover Glass Making Machine, and Japan Second-Hand Optical Processing Equipment. Equipment includes double sided lapping grinding and polishing machine, inner circle cutting optical manufacturing equipment, double head glass engraving machine for making mobile phone cover, mobile screen printing machine, plane and spherical surface milling grinding machine, profiling edging machine, multi wire cutting equipment etc.

If you are interested in any type of optical manufacturing equipment, please feel free to contact us.