-

Optical Quartz Glass

-

Machining Quartz Glass

-

Quartz Glass Tube

-

Quartz Capillary Tube

-

Borosilicate Glass Tube

-

Quartz Glass Rod

-

Laser Spare Parts

-

Silicon Dioxide Sputtering Target

-

Quartz Apparatus

-

Quartz Glass Plate

-

Custom Glass Parts

-

Custom Ceramic Parts

-

Optical Manufacturing Equipment

-

Mobile Glass Cover Making Machine

-

Optical Measuring Instrument

-

Optical Crystal

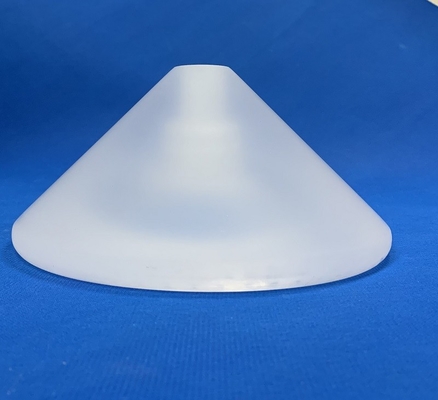

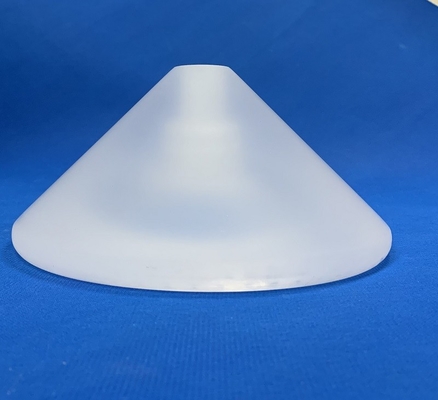

Machining Quartz Glass Cone Frosted Surface Customized Heat Resistance

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Shape | Custom Made | Color | Frosting Or Clear |

|---|---|---|---|

| MOQ | 1 | Tolerance | ±0.1mm |

| Highlight | heat resistance machining quartz glass,frosted surface machining quartz glass |

||

Customized heat resistance Frosted Surface quartz glass cone

| Frosted quartz cone | |

| SIO2 : | 99.9 % |

| Density : | 2.2(g/cm3) |

| Degree of hardness moh' scale : | 6.6 |

| Melting point: | 1732°C |

| Working temperature : | 1100°C |

| Max temperature can reach in a short time : | 1450°C |

| Acid tolerance: | 30 times than Ceramics , 150 times than Stainless steel |

| Visible light transmittance : | above 93% |

| UV spectral region transmittance: | 80% |

| Resistance value : | 10000 times than ordinary glass |

| Annealing point: | 1180°C |

| softening point: | 1630°C |

| Strain point: | 1100°C |