-

Optical Quartz Glass

-

Machining Quartz Glass

-

Quartz Glass Tube

-

Quartz Capillary Tube

-

Borosilicate Glass Tube

-

Quartz Glass Rod

-

Laser Spare Parts

-

Silicon Dioxide Sputtering Target

-

Quartz Apparatus

-

Quartz Glass Plate

-

Custom Glass Parts

-

Custom Ceramic Parts

-

Optical Manufacturing Equipment

-

Mobile Glass Cover Making Machine

-

Optical Measuring Instrument

-

Optical Crystal

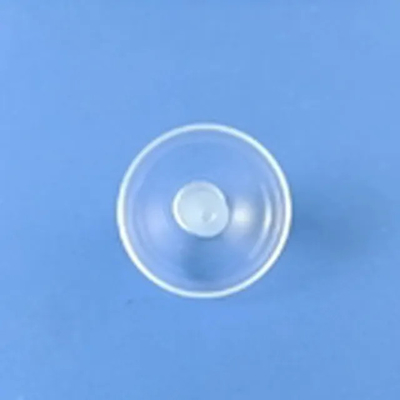

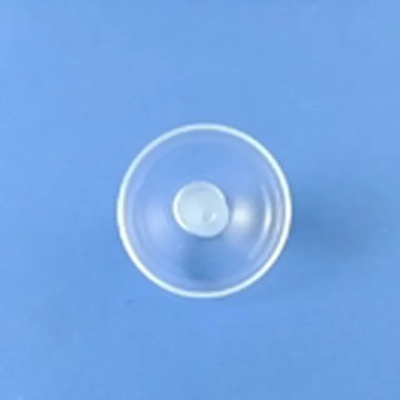

Precision 0.0005mm Optical Quartz Glass Hemispherical Resonator For Hemispherical Resonator Gyroscope

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Highlight | 0.0005mm Hemispherical Resonator,Hemispherical Resonator Gyroscope |

||

|---|---|---|---|

Product descriptions from the supplier

Quartz Hemispherical Resonator For Hemispherical Resonator Gyroscope

All of them are made of fused quartz material with high quality factor and metallized on the surface. As the sensitive part of

the gyro, the hemispherical resonator is the core of the hemispherical resonator gyro. Its machining surface accuracy, position

accuracy and surface quality are the most key factors affecting the accuracy and performance of the hemispherical resonator

gyro. The higher the machining accuracy of hemispherical resonator, the closer it is to the ideal resonator state, and the higher

the gyro accuracy. The hemispherical resonator is made of fused quartz and is a hemispherical thin-walled shell with a central

support rod, with a diameter of φ 15 ~ 60mm, wall thickness is generally 0.3-1.1mm, surface accuracy < 0.5um, inner and outer

ball concentricity < 0.5um, surface roughness Ra < 0.025um, and quality factor Q value is higher than 107. The special-shaped

spherical hemispherical resonator requires high surface accuracy and concentricity of inner and outer spheres, and the accuracy

reaches sub micron level. Due to the hard and brittle quartz glass material, easy edge collapse, crack and embrittlement in

processing, and special processing technology, the conventional processing method of spherical optical elements is not applicable,

the qualified rate is very low, and the processing is very difficult.

After years of technical accumulation, we can successfully produce this part with high accuracy.

![]()

![]()

![]()