-

Optical Quartz Glass

-

Machining Quartz Glass

-

Quartz Glass Tube

-

Quartz Capillary Tube

-

Borosilicate Glass Tube

-

Quartz Glass Rod

-

Laser Spare Parts

-

Silicon Dioxide Sputtering Target

-

Quartz Apparatus

-

Quartz Glass Plate

-

Custom Glass Parts

-

Custom Ceramic Parts

-

Optical Manufacturing Equipment

-

Mobile Glass Cover Making Machine

-

Optical Measuring Instrument

-

Optical Crystal

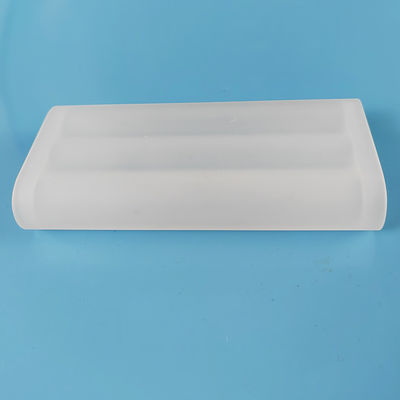

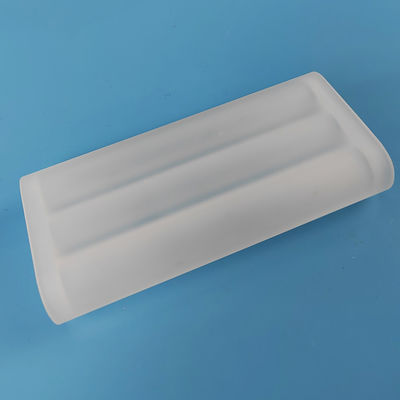

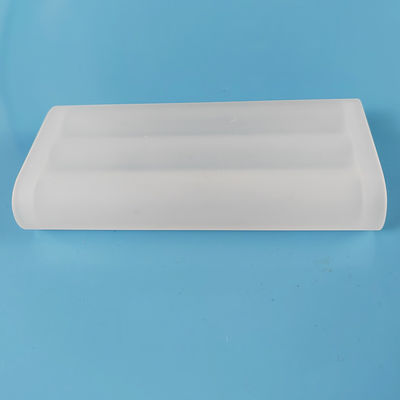

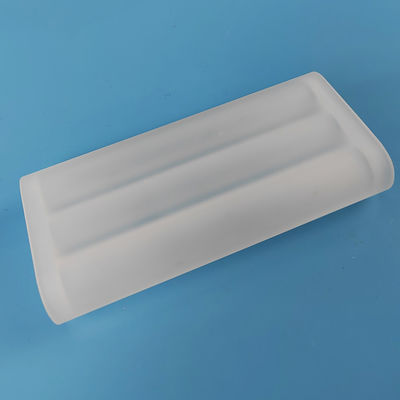

Frosted Quartz Laser Cavity Filter Laser Spare Parts High Precision

| Material | Quartz | Color | Frosted(Not Clear And Transparent) |

|---|---|---|---|

| Shape | Triple Holes | Feature | High Precision, Good Performance, Long Service Life |

| Highlight | frosted cavity filter,quartz cavity filter,high precision cavity filter |

||

Other description: Quartz Flow Tube, Laser Flow Tube, Laser Cavity Filter, Laser Cavity Reflector

Material: Quartz glass

Dimension: Custom length and bore diameter

Holes: Single / Double / Triple Bores

Available material: Borosilicate glass (Pyrex glass), Quartz glass, Cerium Doped Quartz, Europium Doped Quartz, Ti Doped Quartz, Samarium Doped Glass

Function: Transmit deep into the UV range about 200nm.

Application: Candela GentleLase Laser Head Triple Bore. In medical, industrial, and research applications.

Surface: Transparent or grinded

Characteristic: Work in high power and efficiency. Premium quality and long service life.

The laser cavity filters produced by Beijing Zhong Cheng Quartz Glass are in high precision, with strict material selection, high efficiency and long service life, which are well praised by customers.

![]()

Material Properties for Quartz Glass

Physical Properties

| Properties | Value | |

| Mechanical Properties | Density | 2.203g/cm3 |

| Compressive Strength | 1100Mpa | |

| Bending Strength | 67Mpa | |

| Tensile Strength | 48.3Mpa | |

| Poisson's Ratio | 0.14~0.17 | |

| Young’s Modulus | 72000Mpa | |

| Rigidity Modulus | 31000Mpa | |

| Mohs Hardness | 5.5~6.5 | |

| Thermal Properties | Deformation Point | 1280℃ |

| Softening Point | 1680℃ | |

| Annealing Point | 1210℃ | |

| Specific Heat (20~350℃) | 670J/kg.℃ | |

| Thermal Conductivity (20℃) | 1.4W/m.℃ | |

| Coefficient of thermal expansion | 5.5×10-7cm/cm.℃ | |

| Hot Work Temperature | 1700~2000℃ | |

| Short-term Use Temperature | 1300℃ | |

| Long-term Use Temperature | 1100℃ | |

| Electrical Properties | Resistivity | 7×107Ω.cm |

| Dielectric Strength | 250~400Kv/cm | |

| ε/ Dielectric Constant | 3.7~3.9 | |

| Dielectric absorption coefficient | <4×104 | |

| Dielectric loss coefficient | <1×104 | |

Chemical Properties

| Solution | Treatment condition | Corrosion capacity |

| H2O | 95℃ 45(Hours) | 1~2×10-7 g/cm2 |

| 98%H2SO4 | 20℃ 2(Hours) | 1.4×10-8 g/cm2 |

| 60%HNO3 | 20℃ 2(Hours) | 5.0×10-8 g/cm2 |

| 36%HCl | 20℃ 2(Hours) | 15×10-8 g/cm2 |

| 5%NaOH | 100℃ 10(Hours) | 1.35×10-3 g/cm2 |

| 1%KOH | 98℃ 2(Hours) | 68×10-6 g/cm2 |

Purity

|

Name |

Impurities ppm | ||

|

Synthetic (CVD)JGSI |

Oxy-hyd melting JGS2 |

Electrical melting JGS3 |

|

| Al | 0.16 | 17.00 | 14.44 |

| Fe | 0.01 | 0.36 | 1.46 |

| Ca | 0.31 | 1.30 | 2.45 |

| Mg | 0.65 | 0.22 | 0.46 |

| Ti | 0.08 | 1.3 | 4.84 |

| Cu | 0.01 | 0.04 | 0.16 |

| Ni | 0.01 | 0.01 | 0.04 |

| Co | 0.04 | 0.01 | 0.02 |

| Mn | 0.01 | 0.03 | 0.08 |

| K | 0.34 | 0.63 | 2.16 |

| Na | 0.06 | 1.11 | 1.33 |

| Li | 0.01 | 0.63 | 0.81 |

| B | / | 0.08 | 0.05 |

| OH | 1100~1300 | 150~250 | 1~120 |

| SiO2 | >99.999% | 99.99% | 99.92% |

Optical Property

![]()