-

Optical Quartz Glass

-

Machining Quartz Glass

-

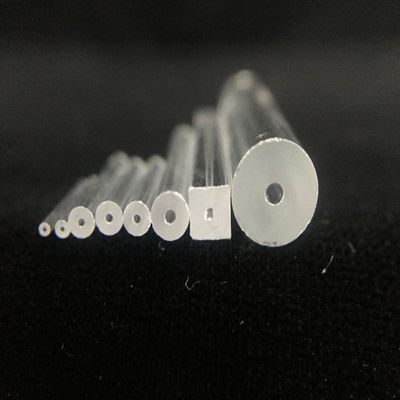

Quartz Glass Tube

-

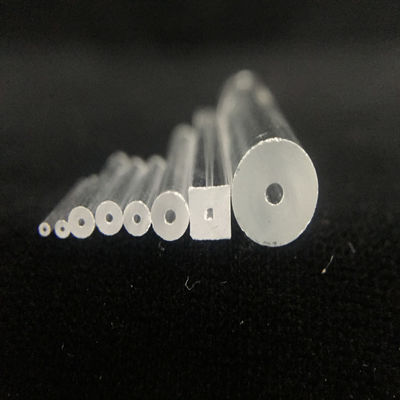

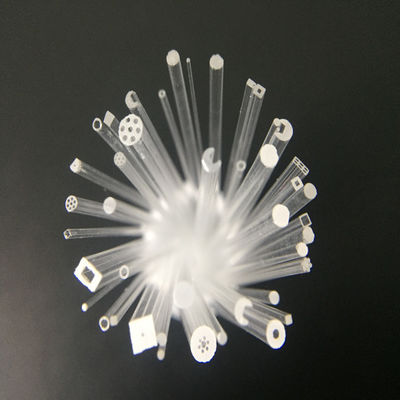

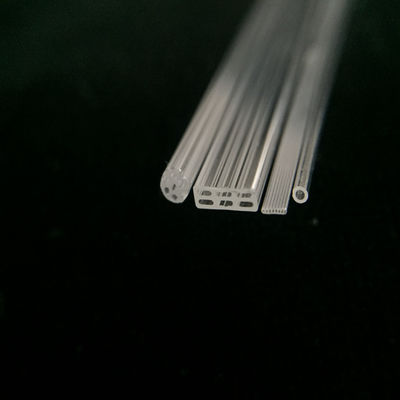

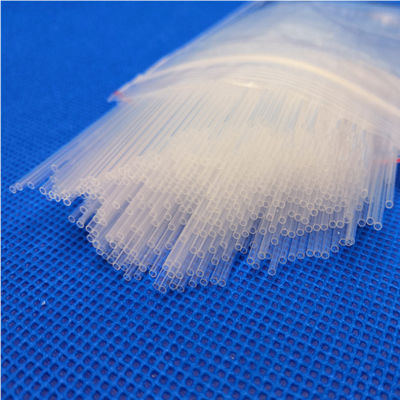

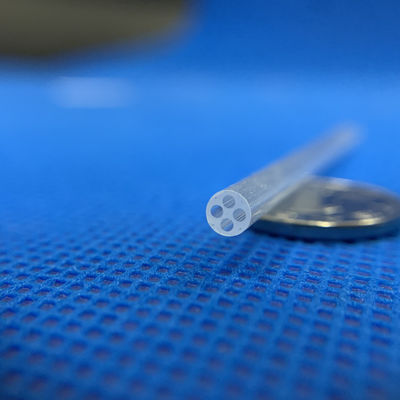

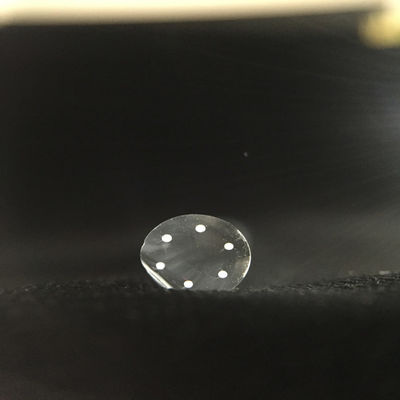

Quartz Capillary Tube

-

Borosilicate Glass Tube

-

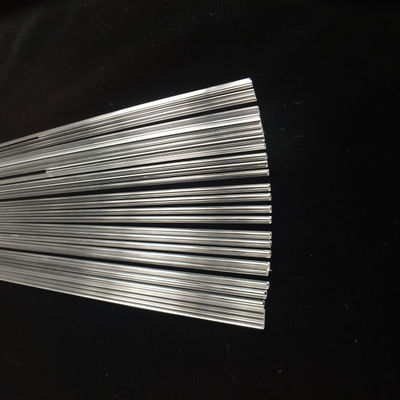

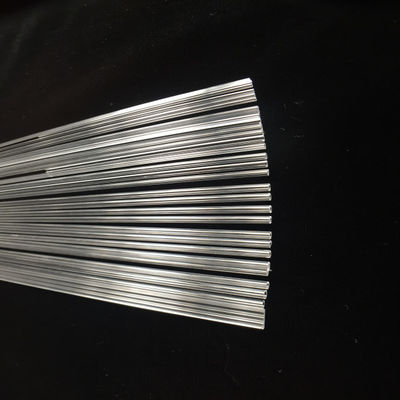

Quartz Glass Rod

-

Laser Spare Parts

-

Silicon Dioxide Sputtering Target

-

Quartz Apparatus

-

Quartz Glass Plate

-

Custom Glass Parts

-

Custom Ceramic Parts

-

Optical Manufacturing Equipment

-

Mobile Glass Cover Making Machine

-

Optical Measuring Instrument

-

Optical Crystal

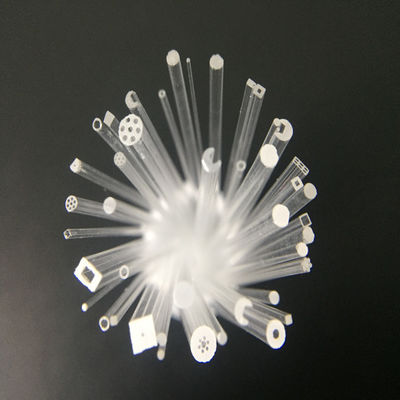

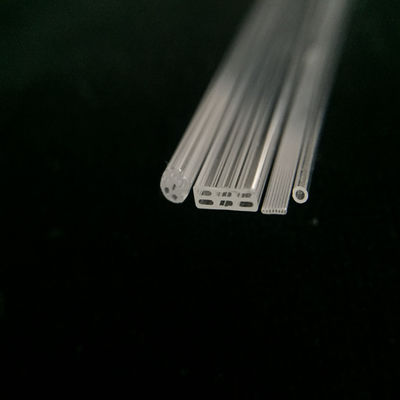

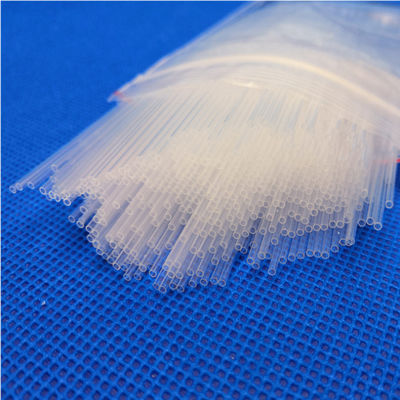

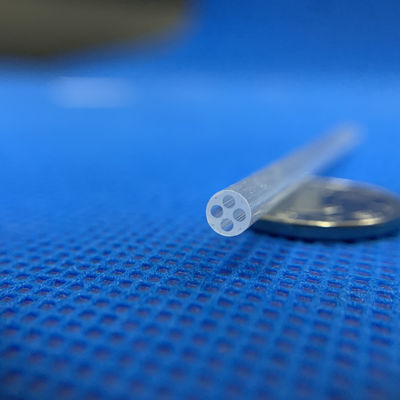

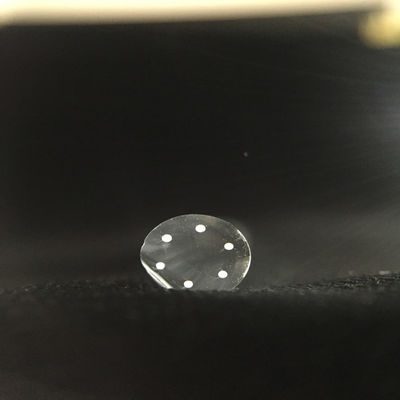

Transparent Heat Resistance Quartz Capillary Tube

| Material | Quartz | Color | Transparent |

|---|---|---|---|

| Shape | Round Capillary Tube | Usage | Semi Conductor, Solar |

| Highlight | transparent quartz capillary tube,heat resistance quartz capillary tube,solar quartz capillary tube |

||

Quartz capillary glass tube transparent heat resistance

In the optical component, the domestic optical quartz glass can be mainly divided into three grades: JGS1, JGS2, and JGS3 according to the spectral application range:

1. JGS1 (Far Ultraviolet Optical Quartz Glass/ Synthetic Fused Silica)

It is an optical quartz glass melted with high purity hydrogenand oxygen. Excellent UV transmission performance, especially in the short-wave UV range, its transmission performance far exceeds that of all other glasses, with a transmittance of 90% at 185nm, which is an excellent optical material in the range of 185-2500nm.

2. JGS2 (Ultraviolet Optical Quartz Glass/ Fused Quartz)

It is an optical quartz glass melted with hydrogenand oxygen. It is a good material in the range of 220-2500nm.

3. JGS3 (Infrared Optical Quartz Glass)

It has high infrared transmission performance, the transmission rate can reach more than 85%. It is an optical material with a wavelength range of 260-3500nm.

Besides domestic materials, we also offer materials in all grades and specifications from major manufacturers such as Corning, SCHOTT and Heraeus. The material has high purity and uniformity, and the finished product has better and more stable performance. Depending on the customer's custom needs, considering the optical, mechanical and chemical properties of the material, we recommend more suitable materials or other specified materialsfor processing.

Optical Property

![]()